ABOUT US

From concept to distribution, we cater to every aspect of the process and are your one-stop shop for the broad base solution of wet / dry granulation consisting of processing system for drying,granulating, mixing, blending, tableting, coating, pelletizing, pellet coating, stirring, homogenizing, vacuumized mixing, filtration, evaporation, containment, material conveying, cleaning as well as process integration.

LOCATION

Ahmedabad

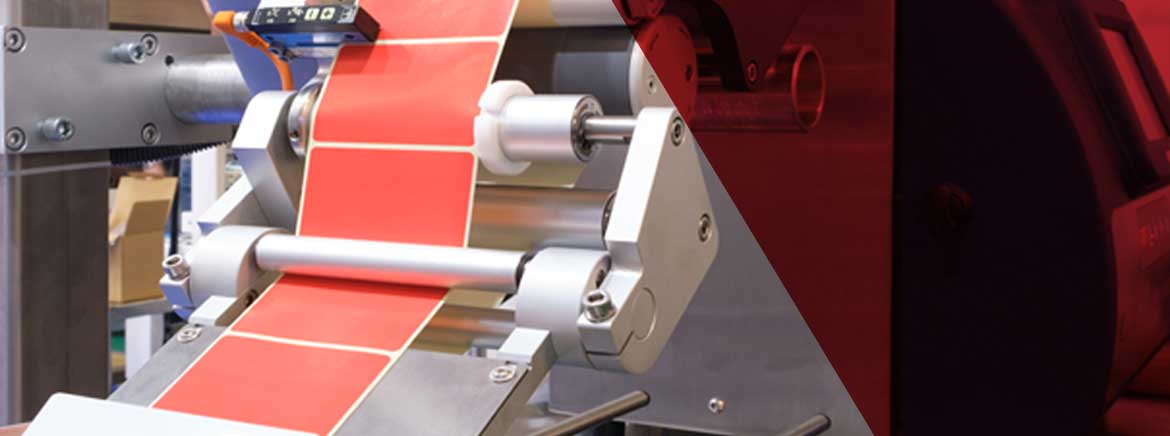

Automatic Double Side (Sticker) Labelling machine is used for double side labelling on flat, oval or square bottles of PET, Plastic, Glass etc. Shapes/Profile. Machine is microprocessor controlled, performs accurately and is very user friendly.

Machine consists of main structure, product in-feed screw, product transmission belt with guide adjustment, top product holding conveyor with height adjustment, 2 nos. of label dispensing unit, label pasting unit, motor, sensors, AC drives, motors, electrical panel, emergency switch and PLC/HMI control for operations.

| Machine | Automatic Double Side Flat Bottle Sticker Labelling Machine |

| Model No. | PLB – ADS 120 |

| Direction of Movement | Left to Right |

| Label size | 10mm to 85mm width |

| Output | Up to 120 bottles/minute |

| Main Motor | 0.5 HP, 1400 rpm, 3 Phase, 430 V, 50 Hz. |

| Conveyor Motor | 0.25 HP/415 Volts/AC/50 Hz Variable Speed |

| Top Pressing Motor | 0.25 HP/415 Volts/AC/50 Hz Variable Speed |

| Stepper Motor | 6 Amp, 60 KG Torque X 2 Nos. |

| Label Length | 240mm Maximum |

| Label Space | 3mm between labels |

| Machine Power | 220 Volts/AC/50 Hz Single Phase |

| Machine Dimensions | 2500mm(L) X 1800mm(W) Conveyor 800mm Ht. 50mm adjustable |