ABOUT US

From concept to distribution, we cater to every aspect of the process and are your one-stop shop for the broad base solution of wet / dry granulation consisting of processing system for drying,granulating, mixing, blending, tableting, coating, pelletizing, pellet coating, stirring, homogenizing, vacuumized mixing, filtration, evaporation, containment, material conveying, cleaning as well as process integration.

LOCATION

Ahmedabad

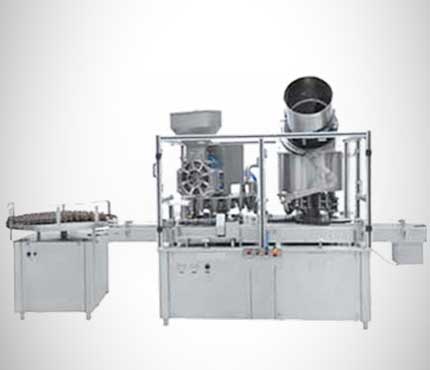

Automatic Rotary Dry Syrup Powder Filling & Capping Machine (monobloc) is suitable for Glass, Plastic, PET, HDPE, and LDPE Bottles with maximum speed of 100 Bottles per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter. The Machine works on time-tested Vacuum and Air Systems to fill powder in Bottle achieving higher speed and higher accuracy. Machine with unique Bottle Lifting and Neck Holding system avoid spillage of powder on bottle shoulder.

- Machine has Stainless Steel structure with all contact parts made from SS 316 Materials and HDPE Funnels.

- No Bottle – No Fill System

- Unique continuous motion Powder Wheel movement for smoother operation.

- Rotary Bottle Movement System with Rotary Funnel System

- Funnel with Unique Vibratory system for filling semi free flow powder at higher speed

- Easy removal system for contact parts Cleaning / Auto Claving / Sterilization.

- Filling Accuracy of +1% to 2% depending on powder at controlled humidity below 30% RH.

- Automatic Infeed and Exit of Bottles through Star Wheel System

- No Bottle at infeed conveyor – Automatic Machine on/off system

- Low Air – Machine Stop System

- Low Vacuum – Machine Stop System

- Low Cap Level – Machine Stop System

- Automatic Cap Feeder On – Off System to avoid damage to the cap avoiding extra movement

- Toughened Glass Safety Cabinet

- Blower for dust extraction.

| Model | PPF-RDFC 80 |

| Bottle Diameter* (In mm) | Up to 85, Square or Rectangular bottles can be used |

| Bottle Height* (In mm) | Maximum 100 |

| Cap | any type of ROPP or Screw Cap, Sample required for evaluation |

| Fill Range | 5gms to 30gms In Single Dose with the help of change parts for different fill volume |

| Fill Accuracy | +1 to 2% Depending upon the Powder, under the controlled level of Humidity |

| Humidity | Below 30% Rh required |

| Electrical | 415 V, AC 3Phase and 220 V, AC Single Phase Power Supply (50 Hz) with A.C. Drive |

| Power | 2.0 H.P. For Machine and 3.0 H.P. For Vacuum Pump |

| Compressed Air | Filtered, Oil Free 2kg/cm2 provided by customer only |

| Vacuum | 28” Hg. @ 500 LPM |

| Conveyor Height (In mm) | 815-940 |

| Overall Dimensions (In mm) | 2500(L) x 1250(W) x 2000(H) |