ABOUT US

From concept to distribution, we cater to every aspect of the process and are your one-stop shop for the broad base solution of wet / dry granulation consisting of processing system for drying,granulating, mixing, blending, tableting, coating, pelletizing, pellet coating, stirring, homogenizing, vacuumized mixing, filtration, evaporation, containment, material conveying, cleaning as well as process integration.

LOCATION

Ahmedabad

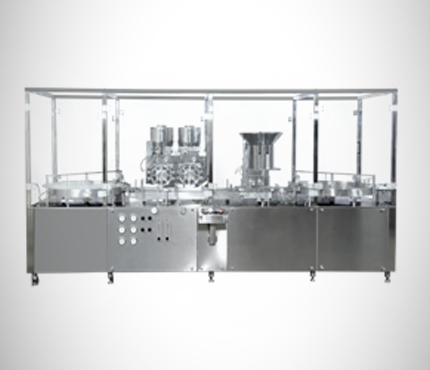

Injectable Dry Powder Filling Machine is suitable for filling dry syrup powder and granules in different type and shape of bottles with max speed of 240 bottles per minute depending on filling volume, type of powder and bottle size.

Sterilized dry container are fed through/guided on Delrin flat conveyor belt at required speed for placement below powder wheel. The sterilized powder stored in hopper is agitated by pair of mechanical agitators. The powder wheel having eight ports rotates at the pre-determined speed. Precise volume of powder is sucked in to the port of powder wheel during vacuum, as per piston length different fill size can be achieved. The time dose of Compressed air (Nitrogen Gas), flushes out powder from the port of powder wheel into the container one by one. Filled containers moves further for Stoppering operation. (Different grooves separator can be used which depends on the container diameter or multiple dosing systems). The sterilized, rubber stoppers stored in the vibrator bowl moves to vibratory bowl and is stacked vertically in the rubber stopper chute. The container is hold firmly between pair or timing belt to pick up rubber stopper from exit end of the chute. Further the container is passed between two pressing rollers for tight fit/fixing of rubber stopper.

- All contact parts are easily removable for Autoclaving / Sterilization.

- All the parts coming in contact with Powder are made of S.S 316L.

- Individual drives for Infeed and Outfeed turntables.

- Safety clutch system to avoid vial breakage.

- A/C Frequency Drive for speed control.

- Pure Air Filters for Air and Vacuum.

- Online Pre – Media Filling System.

- Pre & Post Gassing System.

- Multiple Dosing System.

- Canister Based Powder Loading System.

- Laminar Air Flow System.

- PLC with Touchscreen HMI.

- Dust Extraction Unit.

- Swing Type Conveyor.

| 120 BPM | 240 VPM | |

| Model | PPF-IDP 120 | PPF-IDP 240 |

| Direction | Left to Right | Left to Right |

| Capacity/Min (For Single Dose) | Up to 120 Fills | Up to 240 Fills |

| Vial Diameter (In mm) | 25 to 45 max. | 25 to 45 max. |

| Height (In mm) | 75 max. | 75 max. |

| Rubber Stopper (In mm) | 20 dia. | 20 dia. |

| Electrical Specifications | 1.00 HP For Main Drive. 0.50 HP For Conveyor motor 5 AMP Coils for vibratory | 2.00 HP For Main Drive. 0.50 HP For Conveyor motor 5 AMP Coils for vibratory |

| Fill Capacity | 60mg to 1.5gm Single Dose (with Change Parts) Fill range depending upon vial opening and bulk density of powder. Under controlled Environment (i.e., Humidity less than 25%) | 60mg to 1.5gm Single Dose (with Change Parts) Fill range depending upon vial opening and bulk density of powder. Under controlled Environment (i.e., Humidity less than 25%) |

| Accuracy | ±1% depending upon consistency and uniformity of bulk density of Injectable powder | ±1% depending upon consistency and uniformity of bulk density of Injectable powder |

| Pneumatic Air | Filtered, oil free, sterile low-pressure AIR at 2 kg/cm2 (2/3 bar) | Filtered, oil free, sterile low-pressure AIR at 2 kg/cm2 (2/3 bar) |

| Vacuum line | 20mmHG. (Pump will be supplied by US .) | 20mmHG. (Pump will be supplied by US .) |

| Height of Conveyor (In mm) | Adjustable from 850 To 910 | Adjustable from 850 To 910 |